in Story & News

Creating the Legend of K-Battery

Materials: EcoPro

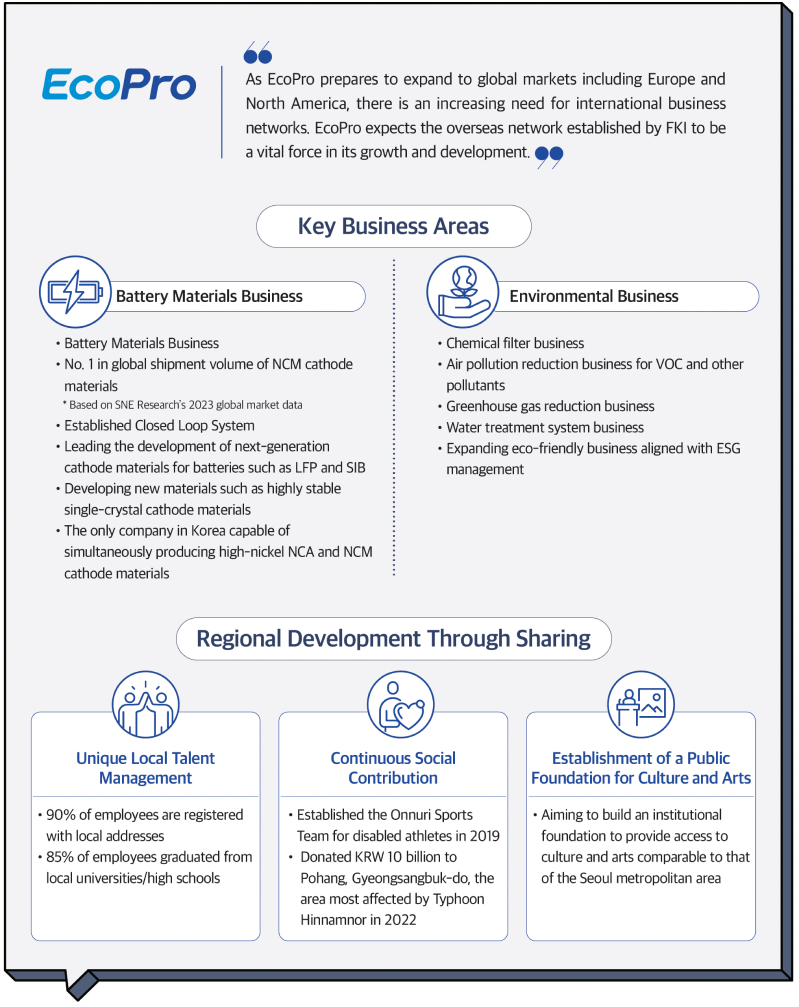

In February, a new name was added to the list of member companies of the Federation of Korean Industries (FKI). As a company that has consistently grown with a dual focus on environment and energy, EcoPro is celebrating its 26th anniversary this October. Meet EcoPro, which has been part of FKI for just over six months.

By Hye-won Kim

Photo credit: EcoPro

Becoming Professionals in Environmental Solutions

EcoPro began its journey in 1998 by developing catalysts to reduce harmful gases emitted in industrial sites, marking its entry into the environmental business. Today, it is one of the leading global companies in the cathode material industry. The company has developed and commercialized technologies for removing harmful gases and preventing air pollution while also expanding its business to secondary battery cathode materials and precursors used in electric vehicles (EVs) and power tools (PTs). EcoPro has not only contributed to the development of Korea’s energy and environmental sectors—such as being the first in the country to centralize technology related to cathode materials—but also established NCA and NCM production bases in North America and Europe, ensuring stable growth in global markets.

EcoPro’s success was not immediate, however. Founder and former Chairman Lee Dong-chae started the company with the motto “Let’s become professionals in the environmental field” with just one employee and KRW 100 million in capital. Approaching its 26th anniversary, EcoPro now leads the domestic and international markets with its nine subsidiaries including EcoPro BM, EcoPro HN, EcoPro Materials, and EcoPro Innovation. Its quantitative achievements are also impressive. As of the end of 2023, the company recorded approximately KRW 7.26 trillion in sales and had about 3,500 employees, cementing its status as a large enterprise.

The First Domestic Battery Materials Company to Enter the Japanese Market

Initially engaged in environmental businesses such as research and development of catalysts for decomposing perfluorocarbons (PFCs), EcoPro made its entry into the secondary battery industry in the summer of 2004. That year, EcoPro had the opportunity to participate in a government project for the development of next-generation secondary battery cathode materials jointly with Cheil Industries. When the cathode material development project failed to secure profitability, however, Cheil Industries withdrew from the business in 2006, and EcoPro acquired it. EcoPro sought to expand its production lines by securing hundreds of billions of won in bank loans in an attempt to supply precursors to a major domestic conglomerate. However, the business hit a roadblock due to aggressive low-cost competition from Japanese rivals, forcing EcoPro to suspend its operations. With half of its revenue wiped out, EcoPro was in desperate need of a break-through.

Former Chairman Lee Dong-chae encouraged his employees to push through and focused on breaking into the market dominated by Japan’s Sony Group Corporation, which was the first to commercialize lithiumion batteries. His chosen strategy was to grow through collaboration networks. EcoPro participated in the battery expo “Battery Japan” to establish a network with Sony. After persistently knocking on doors and receiving technical guidance and validation from Sony, EcoPro became the first domestic battery materials company to supply cathode materials to Japan on a trial basis in 2013. In 2015, EcoPro secured a long-term supply contract for cathode materials. By raising its quality standards, EcoPro successfully penetrated the Japanese market, securing major clients such as Sony and Samsung SDI and leading the company to continued success.

Established

1998

Sales

Approximately

KRW7.26 trillion

As of 2023

Employees

Approximately3,500

Eco-Friendly K-Battery Value Chain Exclusive to EcoPro

In 2015, when the battery cathode material division recorded an annual profit, EcoPro spun off its cathode materials business and established EcoPro BM in 2016. In less than three years, EcoPro BM was newly listed on the KOSDAQ market. By securing an additional KRW 170 billion through the IPO, EcoPro set its sights on building a complete battery value chain. They set up operations in Yeongil-man Industrial Complex in Pohang, Gyeongsangbuk-do where they invested approximately KRW 2 trillion in a 496,000m2 site, creating an ecosystem for battery cathode materials. This marked the birth of the Closed Loop Ecosystem (CLS), Korea’s first and only battery value chain where all processes from battery recycling to cathode material production are integrated.

Through the CLS system, EcoPro significantly reduced the cost of raw materials for cathode materials by internalizing and recycling raw materials. It is now accelerating the development of Closed Loop System Version 2 (CLS V2), which aims to minimize pollutants such as wastewater generated within the battery cathode material ecosystem. CLS V2 is designed to expand battery recycling from cells to complete modules and packs, with the goal of purifying and reusing industrial wastewater. If successfully developed, the system is expected to reduce manufacturing costs by about 30% compared to current levels.

EcoPro is not only competitive in battery materials but also excels in the environmental business. Established in 2021 after the spin-off of EcoPro’s environmental business division, EcoPro HN leads the eco-friendly industry as an air pollution prevention and post-treatment specialist. It has entered various new business sectors including cleanroom chemical filters, greenhouse gas reduction solutions, fine dust reduction solutions, secondary battery materials, and semi-conductor process materials. EcoPro HN plans to take a major leap forward with its second campus located at Chopyeong Industrial Complex in Jincheon-gun, Chungcheongbuk-do, which is expected to be completed in the fourth quarter of this year.

Signed a long-term contract with Sony

for cathode material supply in 2015

View of the Pohang campus